In the oilfield industry, dealing with paraffin and scale buildup has traditionally been an expensive and ineffective process. Operators have resorted to pouring dangerous chemicals and using mechanical scraping and heat treatments, all of which cause irreversible damage to the wellbore and equipment. These methods are only short-term fixes and do not provide a permanent solution to the problem.

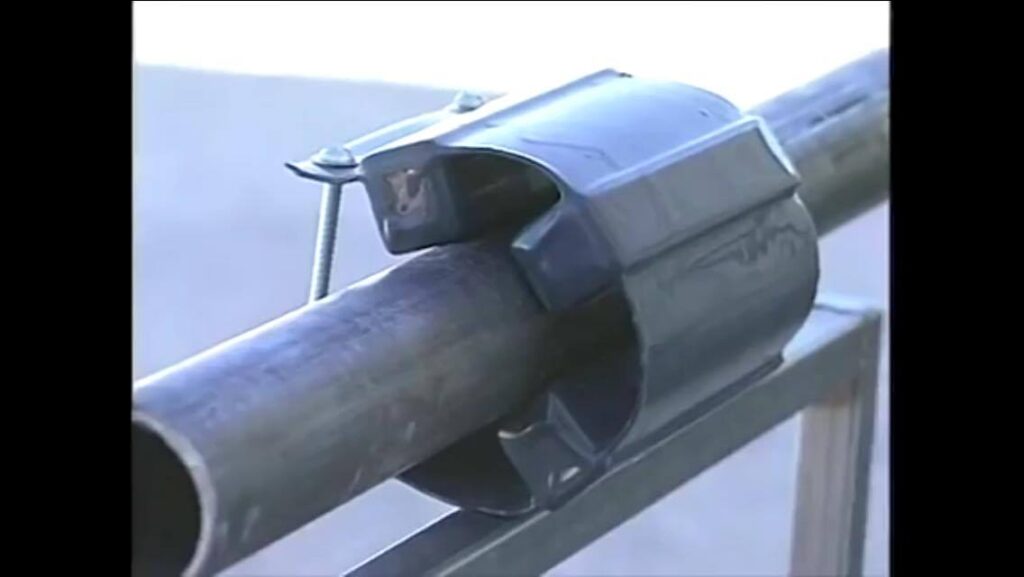

But with Magniflo, we offer a smarter and more efficient approach. Our tools are designed to prevent paraffin buildup in the wellbore, eliminating the need for costly and time-consuming manual removal of paraffin clogs. By inhibiting the buildup of paraffin and scale, our technology enhances the performance of the well, increasing production and reducing operating costs. Plus, our tools are durable and long-lasting, providing a solution that will last the lifetime of the well and can even be used in other wellbores. Choose Magniflo for a sustainable and effective solution to your paraffin and scale buildup challenges.

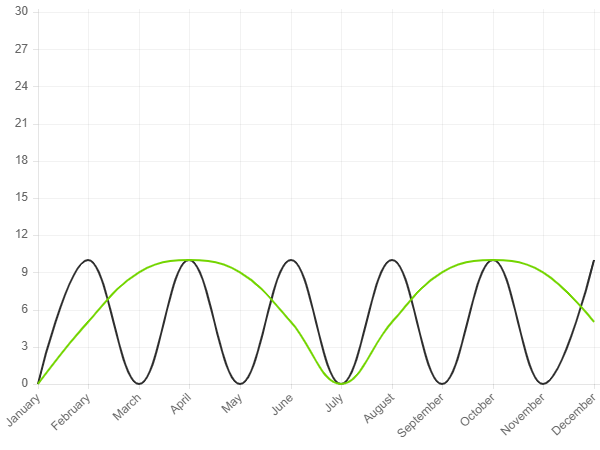

By reducing paraffin and scale buildup in the wellbore, Performance of the well can be greatly improved in many aspects: from an increase in overall production, to reductions in operating costs, downtime and chemical and mechanical servicing.

MagniFlo tools, when installed as designed can inhibit paraffin/scale buildup which will allow the well to perform and produce at its optimum, providing you with the potential to see a marked increased in production that is possible through the relatively planar curve that a clean wellbore will show.

MagniFlo Tools lose their magnetic flux rating ( gauss rating) in decades, losing less than 1% of their overall magnetic rating in 100 years. MagniFlo tools will continue to work in your wellbore long after production has declined and will out live the life of the well, and can be retrieved and used in other wellbores if the need arises. Our full bore tubing tools are made from standard tubing subs and is the only limiting factor of our design.

The deposition of even minute particles of hydrocarbons and minerals is not only conductive to corrosion but reinforces and promotes that same corrosion. When this depositiositional matter precipitates from colloidal suspension, because of its chemical composition and / or other influences(such as changes in the rate of flow, temperature, pressure, degrees of saturation and vibration), crystallization occurs. This crystallization, once initiated, continues unabated and increases exponentially (the worse it gets, the worse it gets) to the point where production decreases and operating costs skyrocket. This is a very significant income loss in high production wells.

If the equipment is permitted to operate as the manufacturer designed it to operate, mechanical failure, repair labor, lift costs, transmission costs and overhead will be significantly reduced as a result. On top of all that, the extended time frame between needing to treat the well significantly increases profit and production per application.

We are here to serve you whether you are interested in PetroFlo products for the Petroleum Industry or in HydroFlo products for scale and mineral salts inhibition in Industry and Commerce.

All MagniFlo products are manufactured of the highest quality materiels available.